SERVICES & COMPETENCES – WHAT WE CAN DO FOR YOU?

Due to our broad range of services, we can deliver small plants and complex and ready-to-use complete plants from one source.

We are happy to help you with the whole project handling as needed. Our all-round service includes the individual consulting beforehand of your project, the planning and development of your plant according to your requirements, the engineering as well as the technical documentation, in-house manufacturing and the subsequent inspection of your plant in the factory, the local mounting and commissioning of your plant as well as the targeted instruction of your personnel.

Are you planning a new project? We are happy to provide you with an individual and non-binding offer. Feel free to contact us!

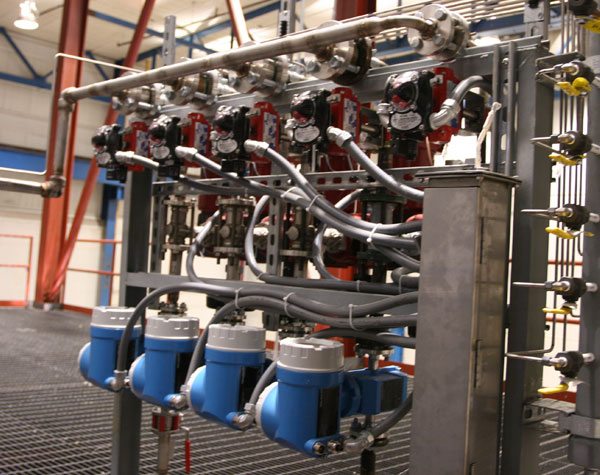

INSTALLATION & MAINTENANCE

Infa Prima PLT is always a professional technical company that is equipped with a suitable tool, mechanical drawing, electrical loop diagram, and instrument loop diagram for the fabrication, improvement, and upgrading of your sequences, designs, and processes. The team is also committed to providing regular maintenance services to ensure the smooth operation of your systems. Infa Prima PLT offers flexible maintenance schedules and quick response times to minimize downtime and maximize productivity. Infa Prima PLT services include the following: -

- Electrical Design and Diagram.

- Electrical Control System.

- Control Panel Fabrication.

- Machine Electrical & Mechanical Installation.

- Factory/Building/Resident M&E maintenance

- Equipment/System integration.

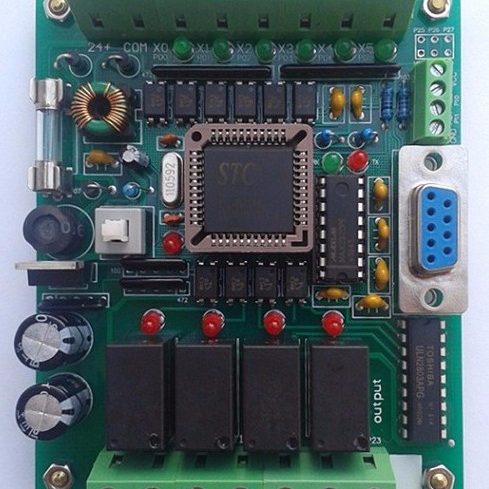

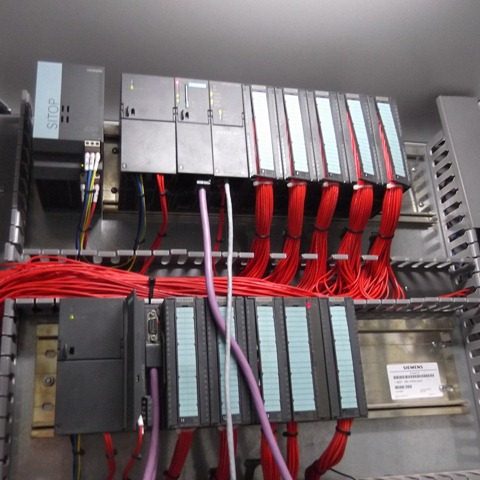

ELECTRICAL AUTOMATION

Infa Prima PLT also develops the programming according to the process sequence of the machine functionality required. With customer permission, programming support can be provided by internet remote access to the machine. This allows for efficient troubleshooting and maintenance, as well as the ability to make adjustments and updates to the system without the need for on-site visits. Additionally, Infa Prima PLT offers training for operators and maintenance personnel to ensure proper use and upkeep of the electrical automation system. The service includes: -

- PLC & HMI programming development.

- SCADA & PC programming development.

- Testing & Commissioning.

- Maintenance & Repair.

***Siemens, Allen Bradley, Mitsubishi, Beckhoff, Delta, Omron, and more.

MOTOR & DRIVE CONTROL

Control and drive engineering are crucial for machinery functionality and operation, and their integration is essential for efficient development. Infa Prima PLT leverages the integration of electrical drive technology with the control program's development environment, handling tasks like hardware planning and software development. The company offers remote maintenance and a commitment to executing customer-requested processes effectively and efficiently. By leveraging these opportunities, Infa Prima PLT ensures the functionality and cost-efficiency of its systems and machines.